|

I use a

stereoscopic microscope to check different aspects of

manufacture (sharpness of cutting edges, condition of

surfaces, porosity of different types of wood), which

illustrates my whole approach to my work. Nothing is

left to chance be it the brand of abrasives I use, the

length of immersion time in linseed oil, the steel

quality of my tools, the sharpening processes, etc,

everything is tested, checked and regularly revised. |

|

The design of the instrument.

Many different fingerings and pitches have been used during the

history of the recorder. For practical reasons, the pitches most

used today are 415 and 440 Hz. The 460 pitch applies essentially to

Consort Renaissance recorders, used for a specific repertoire. The

most common fingerings are the Baroque, the ancient (or Hotteterre),

and the Ganassi fingering (similar to the ancient fingering on the

first octave and a half).

|

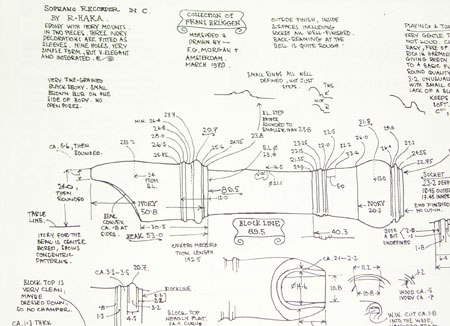

Because of this

multiplicity of fingerings and pitches, more often than not

the recorder maker must base his work on historical models.

Some of these were measured and drawn with great care by

their manufacturers. Fred Morgan, especially, left us

extremely interesting, precise and detailed plans. |

|

The

conversion of the pitch is done following very simple homothetic

mathematical relations but there is an inevitable modification of

the tone of the instrument. Often, the fingering has to be adapted.

Modern fingering (erroneously called Baroque) is unfortunately

unavoidable today. Since recorder fingering has changed so often

during the history of the instrument, was it really necessary to

invent this one? I would have preferred to keep the Hotteterre

fingering, since it facilitates playing on instruments nearer to the

originals, but modern fingering is so widespread today that it is

unlikely to be abandoned.

The range must sometimes

be increased, as is the case with the Ganassi recorder or the

Renaissance recorder. In his Treatise, Sylvestro Ganassi included a

fingering table for a recorder with a vast range, so it seemed

reasonable for musicians to demand such an instrument. However,

since this range was not entirely used in the examples of

diminutions which followed, we presume it was not that easy to play

it. The makers were thus led to make this flute fit for use over two

and a half octaves, but without real historical justification.

Another problem is the

temperament. Our modern ears are used to the homogeneity of the

equal temperament but unequal temperaments bring a color and unique

expressivity to instruments, even in solo works. The electronic

tuner is a precious aid but should be used with precaution. I advise

all musicians to use this excellent tool with circumspection. By its

use, we have compelled manufacturers to come nearer and nearer to

using equal temperament, which presents little interest for a

recorder. Deviations of 35 cents between two notes (Do sharp and Mi

flat for example) can be found on a perfectly tuned flute with

Mesotonic temperament. Among the best known, the most moderate

temperament is Valotti, which I recommend to you for baroque

instruments if you are a novice.

Making the recorder

The wood used must be left

to dry for four or five years, more if possible. The ideal is to

have a stock of wood cut or bought by a far-sighted parent. Happily,

my father assembled a stock of boxwood, maple, pear, African

blackwood (grenadille), Brazilian rosewood and bubinga during the

years 1975 to 1980. Of course, I renew this stock regularly for

future use.

But length of the drying

period is not the only criterion. I attach a particular importance

to letting the wood rest for some months between the diverse phases

of manufacture. I let two or three months elapse between the

roughing out, boring, turning and finishing operations. Boxwood

undergoes a specific treatment: it is plunged into hot oil to

complete drying and eliminate the internal tensions which have

accumulated during growth.

|

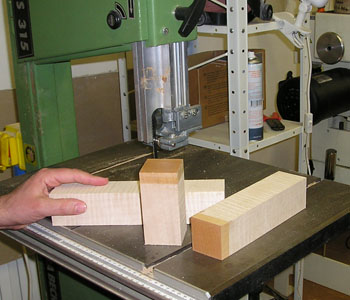

Cutting up lengths

is done with a band saw.

Strict selection is already carried out at this stage. |

|

|

The corners are

removed before turning |

|

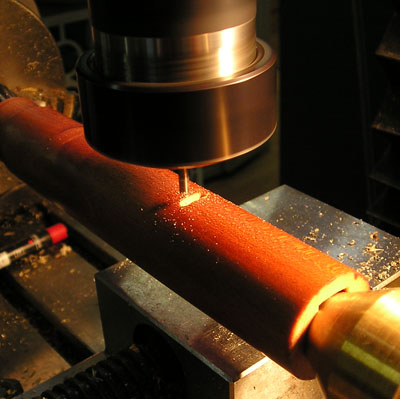

Rounding off and

cutting lengths are done on a CNC lathe to guarantee

geometric precision. This simplifies the drilling and

boring operations and gives a better final result. |

|

Again, some pieces go from

the workbench to the dustbin as the first turning operation can

reveal hidden faults inside the piece.

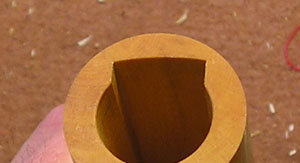

Drilling is the next

operation. To obtain better centering, the wood turns and the drill

stays immobile. A first cylindrical hole is made with a tool which

takes away a great deal of material, such as an air drill.

With this type of tool

precise drilling can be done without generating heat as the shavings

are progressively evacuated by compressed air.

Finishing is done with a

special cutting tool called a "reamer". Unlike the classic

helicoïdal drill which cuts at its extremity and can therefore only

make a cylindrical hole, the reamer has a cutting blade along its

whole length, making a conical hole with a excellent finish. The

reamer reproduces its own shape inside the drilled hole, thus making

it possible to obtain a bore of complex form. A different reamer is

required for each interior form . Reamers are very important tools,

specific to the manufacture of wind instruments.

|

I make mine in my

workshop where they are turned on a high precision CNC

lathe. The blades are cut with a milling machine, a very

useful tool to have in a workshop. |

|

|

|

To cut the windway,

I use a machine I have specially adapted which allows me to

duplicate the appropriate curve inside the head of the

recorder with great precision. |

|

The result is a

rough cut close to the final objective which gives me a good

foundation on which to work. |

|

|

Turning is done by

hand for some instruments or with a digital command lathe

for others. This complicated machine executes work of such

high quality that one forgets how difficult it is to

operate. Whether or not it is done by hand, turning creates

the aesthetic appearance of he recorder but the actual

creative part, which gives the instrument its individual

sonority, comes much later in the process. |

|

|

|

Polishing and

staining gives a unique character to each instrument. Finer

and finer abrasives (up to grain 1200) are passed one after

the other and the piece is then finished with a polishing

paste. The final result depends in part on the sharpness of

the tools used for turning. |

Recorders of simple form

like the Ganassi and the Radi can be varnished French fashion with

shellac, particularly if they are in light-colored wood and not

stained. Those more complex in form, like baroque recorders or those

in darker wood like African blackwood are simply polished.

In all cases, the recorder

is treated with linseed oil to improve its acoustic qualities and to

limit exchanges of dampness with the air. Staining is done in the

old style using nitric acid, among other things, and following a

strict process of preparation and finishing. This type of stain has

shown an exceptional resistance over time as we can see from

historical instruments.

|

The window is cut

on a milling machine, the head of the recorder being held on

a special support. |

|

|

|

I have a 4-axis

piloted milling machine to realize different operations,

notably drilling the finger holes in the body. Of course,

this machine is over-sophisticated for such work but it

offers great precision, notably for drilling at an angle.

Failing this, one can trace the hole and use a traditional

drill press. |

I also make excellent

rough cuts of blocks for the most common models with this machine.

|

An excellent result with a nice, clean cut. |

|

From this moment on,

lathes, drills and other machines are set aside. Now we have the

most time-consuming and interesting part of the work which I do at

my desk with simple traditional tools.

|

The labium is cut

by hand with a wood chisel and finished with special tools.

|

|

|

|

The block is

carved in a piece of cedarwood after two shoulders have been

turned corresponding to the inside diameter of the head,

which serve as points of reference. |

|

It is dovetailed

into the head of the recorder to give a perfect fit without

forcing. |

|

|

|

The windway is

worked with fine abrasives and the window finished with

diverse small tools like fine files and scalpels. |

|

The scalpel is

also used to flare out the holes of the body and foot, which

is one of the methods of tuning the recorder.

|

|

Some types of wood are

sensitive to humidity in the first few hours of life of the

instrument and require many adjustments before the wood settles down

and stabilizes.

Some aspects of the

finished recorder can be judged objectively: ease in the higher

register, stability in the lower register, the pitch. But the

sonority, the ease of interpreting the musical intention and the

comfort of playing are much more subjective. This is when the

recorder maker can become really creative, as he models the sound

and personality of the instrument. The regulation of the beak is a

work of great finesse, which requires delicacy and patience.

The recorder is played,

tried out then adjusted as often as necessary until it becomes a

unique instrument facilitating easy musical expression and giving

the player a real pleasure. |